Sheet Metal Laser Cutter: Precision, Efficiency, and Cost-Effectiveness in Metal Fabrication

Looking for a high-precision solution for cutting metal sheets? Discover the benefits of a sheet metal laser cutter, its working mechanism, applications, and how it enhances efficiency in metal fabrication.

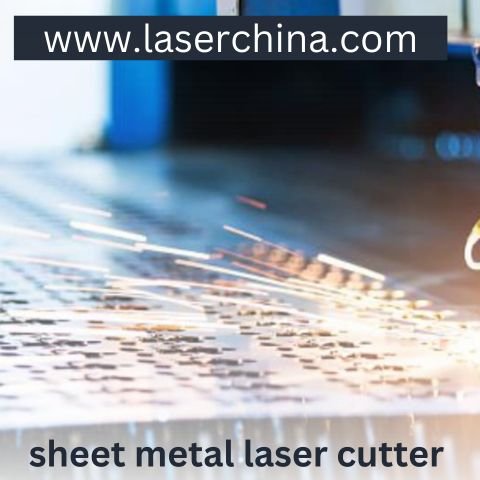

Metal fabrication has evolved significantly with advancements in technology, and one of the most revolutionary tools in this industry is the sheet metal laser cutter. These high-precision machines use laser beams to cut through various metal sheets with unmatched accuracy and speed. Whether used in industrial manufacturing, automotive production, or custom metalworks, laser cutters have transformed the way professionals handle metal fabrication.

In this article, we’ll explore how sheet metal laser cutters work, their advantages, applications, and why they are an essential tool for modern industries.

How Does a Sheet Metal Laser Cutter Work?

A sheet metal laser cutter operates by directing a high-powered laser beam at the metal surface. The laser’s energy melts, burns, or vaporizes the material, creating a clean and precise cut. The process is controlled by computer-aided design (CAD) software, ensuring extreme precision and repeatability.

Key Components of a Laser Cutter:

- Laser Source – Generates the laser beam used for cutting.

- Cutting Head – Focuses the laser beam onto the metal surface.

- CNC Control System – Controls the movement and intensity of the laser.

- Assist Gas – Helps remove molten metal and improves cutting efficiency.

Benefits of Using a Sheet Metal Laser Cutter

1. High Precision and Accuracy

Laser cutters provide superior accuracy, making them ideal for intricate designs and detailed cuts. Unlike traditional cutting methods, they ensure minimal material waste and excellent edge quality.

2. Speed and Efficiency

Compared to mechanical cutting methods, laser cutters work significantly faster. The automation in CNC-controlled laser machines reduces production time while maintaining consistent quality.

3. Versatility in Materials

Sheet metal laser cutters can work with various metals, including:

- Stainless steel

- Aluminum

- Mild steel

- Brass

- Copper

4. Cost-Effective Production

While the initial investment in a laser cutter might be high, the long-term benefits include reduced labor costs, minimal material waste, and increased production speed, making it a cost-effective choice for manufacturers.

5. Minimal Maintenance and Wear

Since laser cutting is a non-contact process, there is no physical wear and tear on the machine’s parts. This reduces maintenance costs and ensures a longer lifespan for the equipment.

Applications of Sheet Metal Laser Cutters

1. Industrial Manufacturing

Industries rely on laser cutters for producing precision parts used in machinery, automotive, and aerospace applications.

2. Custom Metal Fabrication

From artistic metalwork to personalized signage, laser cutters allow for customized designs with flawless accuracy.

3. Electronics and Electrical Components

Laser cutters are essential in producing intricate metal parts for circuit boards and electrical enclosures.

4. Automotive and Aerospace Industry

These industries benefit from laser cutting for manufacturing lightweight yet strong metal parts with high precision.

5. Construction and Architecture

Laser cutters are used for creating detailed metal panels, railings, and structural components in modern buildings.

Choosing the Right Sheet Metal Laser Cutter

When selecting a sheet metal laser cutter, consider factors such as:

- Power Output – Higher wattage for thicker materials.

- Cutting Speed – Determines efficiency for mass production.

- Software Compatibility – Ensure it supports CAD/CAM software.

- Maintenance Requirements – Look for a machine with low maintenance needs.

Conclusion

A sheet metal laser cutter is an essential tool in modern metal fabrication, offering precision, speed, and cost-effectiveness. Whether for industrial or custom applications, laser cutting technology continues to shape the future of manufacturing. Investing in the right laser cutter can streamline your operations and enhance productivity, making it a worthwhile addition to any metalworking business.

What's Your Reaction?